Our process

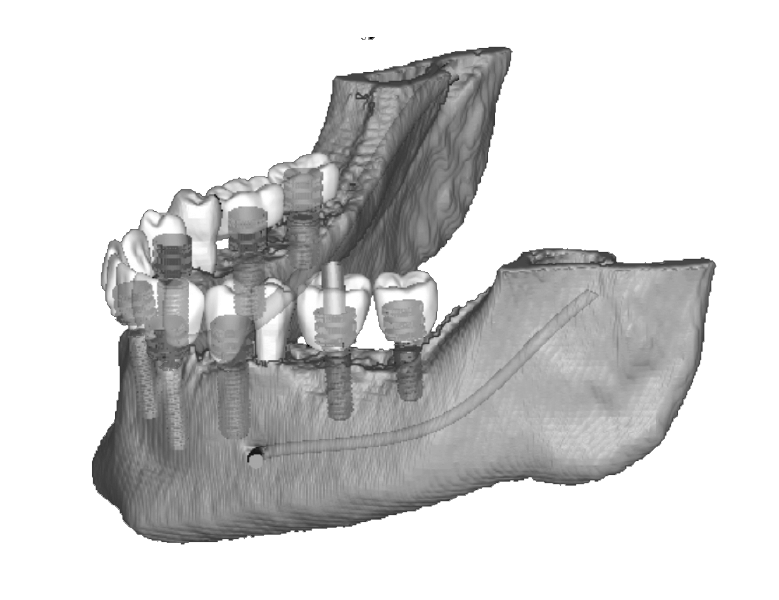

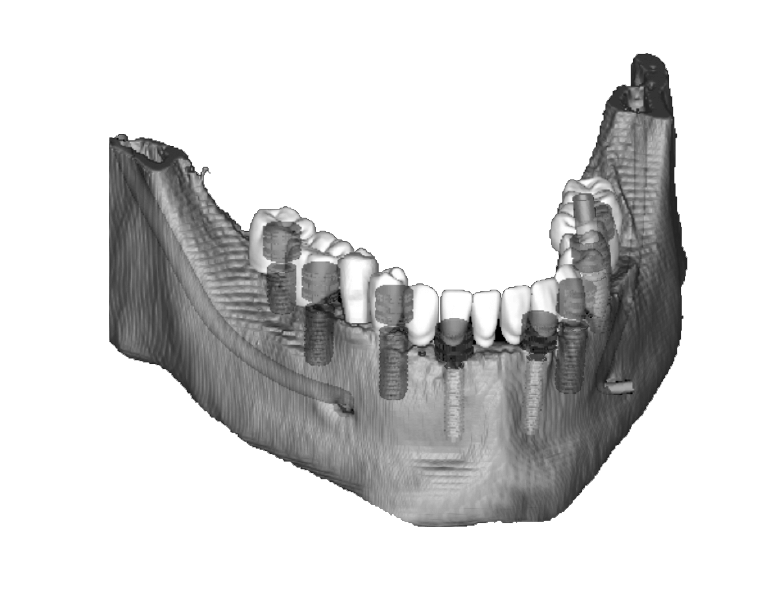

Our approved workflows both traditional and digital are 100% controlled by us and eliminates the inconsistencies found in comparable methods, guaranteeing you the most accurate restoration possible. We maintain an adjustment rate dramatically lower than industry standard.

Together with invaluable traditional experience we have equipped ourselves with the most advanced digital dental technologies available, allowing us to provide you with gold-standard service and unique products.